Services

DESIGN

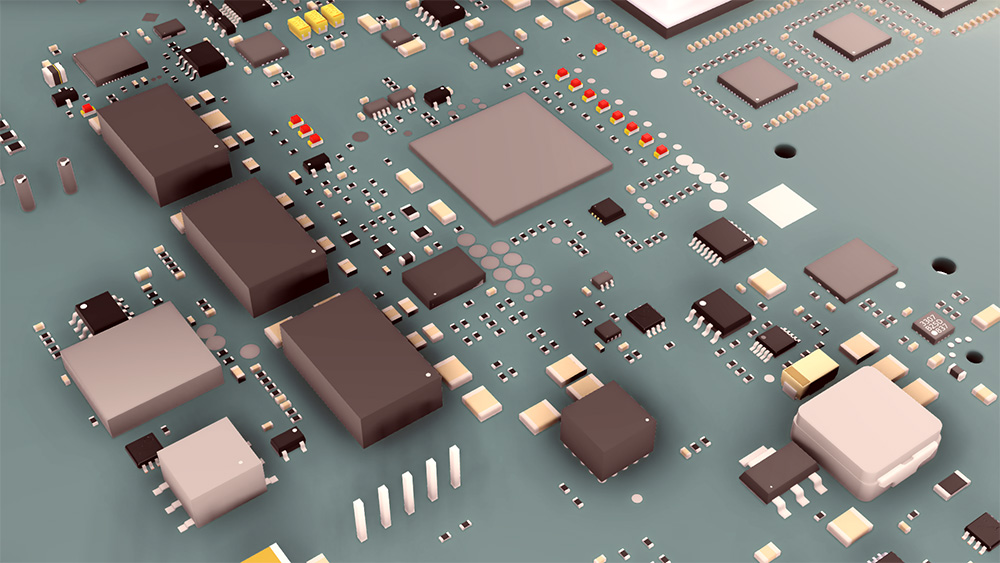

Dense design for demanding industries

Elix offers comprehensive electronics design services, leveraging a team of highly skilled and experienced professionals proficient in both electronics and FPGA design. We ensure adherence to rigorous design assurance processes and certifications, including DO-254 and DO-178 for software, CE certification, to meet the stringent requirements of aerospace and defense.

Expertise in Design Assurance and Certification

Elix’s team specialises in electronics and FPGA design with specific focus on imaging and sensor fusion. Our experience in design assurance processes and certifications, such as DO-254 for airborne electronic hardware, DO-178 for software considerations in airborne systems, and ISO 13485 for medical devices, ensures that designs meet regulatory and compliance requirements.

Integrated Design and Development

Our services encompass the complete design and development lifecycle. Based on customer specifications, we design and develop schematics, PCB layouts, FPGA configurations, Board Support Packages (BSP), and software code for each project. We also handle the design of corresponding mechanical components to ensure complete system integration and delivery.

Cost-Effective Nearshore Capabilities

Our core team of experts in electronics design is complemented by our nearshore site in Novi Sad, Serbia. This facility provides cost-competitive, scalable services for design, testing, and qualification. It enables us to deliver high-quality solutions while optimizing costs and scalability.

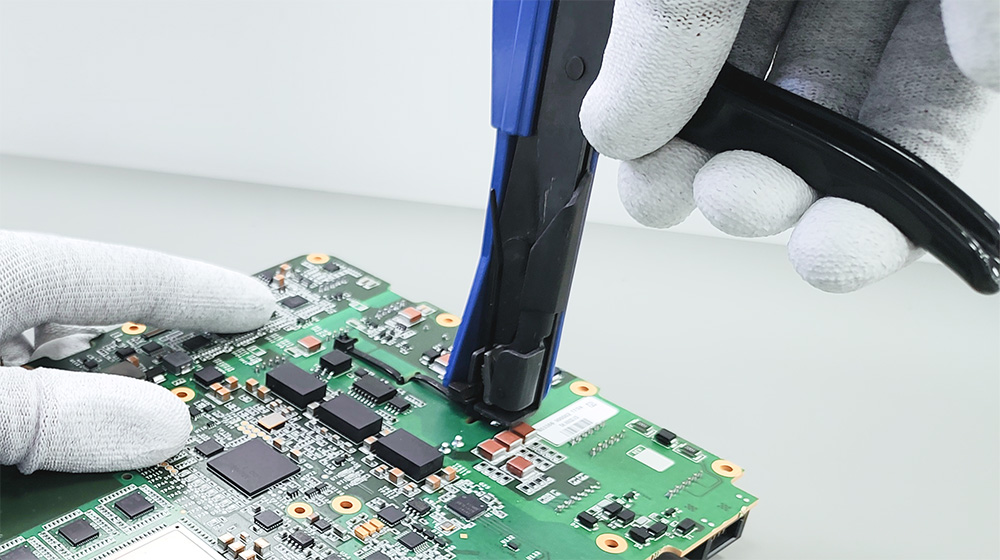

Prototyping and Design Verification

We manufacture in-house prototypes and perform thorough bring-up and verification of the designs. This includes the production of prototypes to validate design concepts and conducting rigorous testing to ensure that the prototypes meet all specified performance and reliability criteria. Fast prototyping and rapid availability of hardware is paramount to the weeding out of problems early in the project lifecycle and the project’s success.

Comprehensive Documentation and Support

We provide detailed documentation for every phase of the design process. This includes complete design documentation, test and verification reports, and support materials to facilitate a smooth transition to production and deployment.

QUALIFICATION

Environmental Test services

DO-160 certification ensures avionics hardware meets rigorous environmental standards for reliable operation in aviation. Together with our partners we perform the necessary tests to meet those standards.

Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC) testing ensures that equipment does not emit or suffer from electromagnetic interference. This includes measuring emissions from the equipment to verify compliance with standards, assessing emissions conducted through power and signal lines, testing the equipment’s immunity to external electromagnetic fields, and ensuring resistance to interference conducted via power and signal lines.

Temperature and Altitude

We conduct thorough tests to ensure equipment performance under various environmental conditions. This includes assessing functionality at extreme temperatures and simulated altitudes. We also evaluate the effects of rapid temperature changes to determine how well the equipment adapts to sudden shifts in environmental temperature. These tests confirm the equipment’s resilience and reliability under temperature variations and high-altitude conditions.

Vibration

Vibration

Our vibration testing evaluates the equipment’s resistance to mechanical vibrations typically encountered during flight. This involves subjecting the equipment to controlled vibrations to simulate the mechanical stresses experienced in operational environments. These tests ensure the durability and stability of the equipment under vibrational stress.

Humidity and Fungus

We test the equipment’s resistance to high humidity levels and potential fungal growth. This involves simulating prolonged exposure to humid conditions to assess performance, and evaluating susceptibility to fungal growth to understand its impact on equipment functionality. These tests ensure that the equipment can operate effectively in environments with high moisture levels.

Sand and Dust

Our sand and dust testing evaluates how well the equipment withstands infiltration by sand and dust. This involves exposing the equipment to sand to test filtration and resistance, and simulating dusty conditions to assess the impact on functionality. These tests ensure the equipment’s reliability in sandy and dusty environments.

Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC) testing ensures that equipment does not emit or suffer from electromagnetic interference. This includes measuring emissions from the equipment to verify compliance with standards, assessing emissions conducted through power and signal lines, testing the equipment’s immunity to external electromagnetic fields, and ensuring resistance to interference conducted via power and signal lines.

Temperature and Altitude

We conduct thorough tests to ensure equipment performance under various environmental conditions. This includes assessing functionality at extreme temperatures and simulated altitudes. We also evaluate the effects of rapid temperature changes to determine how well the equipment adapts to sudden shifts in environmental temperature. These tests confirm the equipment’s resilience and reliability under temperature variations and high-altitude conditions.

Vibration

Our vibration testing evaluates the equipment’s resistance to mechanical vibrations typically encountered during flight. This involves subjecting the equipment to controlled vibrations to simulate the mechanical stresses experienced in operational environments. These tests ensure the durability and stability of the equipment under vibrational stress.

Humidity and Fungus

We test the equipment’s resistance to high humidity levels and potential fungal growth. This involves simulating prolonged exposure to humid conditions to assess performance, and evaluating susceptibility to fungal growth to understand its impact on equipment functionality. These tests ensure that the equipment can operate effectively in environments with high moisture levels.

Sand and Dust

Our sand and dust testing evaluates how well the equipment withstands infiltration by sand and dust. This involves exposing the equipment to sand to test filtration and resistance, and simulating dusty conditions to assess the impact on functionality. These tests ensure the equipment’s reliability in sandy and dusty environments.

Contact us to discuss your requirements and how we can help you manage your projects all the way to qualification. Our engineering team can help you identify the qualification needs and if any custom test benches and cables are required. We can then specify them together with you and plan their availability in order to build the full qualification test plan.

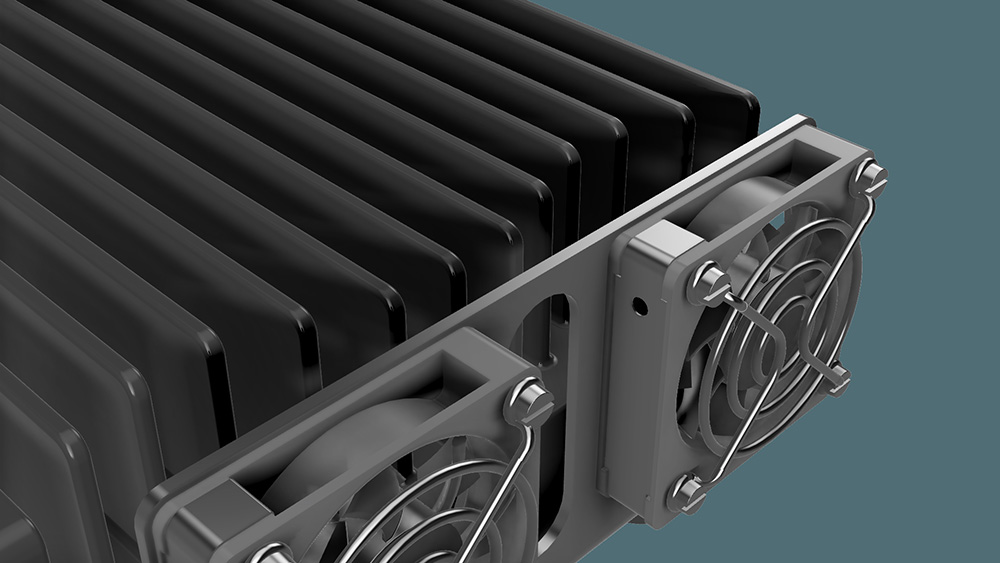

System Integration

Integration of complex systems

Elix excels in delivering comprehensive system integration solutions, ensuring that diverse components and subsystems work seamlessly together to meet complex project requirements. Our integration services span across various domains including aerospace, defense, and medical systems, providing a robust framework for developing, validating, and deploying fully integrated solutions.

End-to-End System Integration

We provide complete end-to-end system integration services that encompass all stages of development, from initial planning and design through to final verification and deployment.

- Planning and Design: Develop a holistic integration plan and strategy, including system/sub-system requirements validation and traceability.

- Subsystem Integration: Assemble and integrate individual subsystems and disciplines into the final system.

- Verification: Conduct comprehensive multi-level testing to ensure seamless operation and interface compliance.

Hardware, Digital design and Software Integration

Elix specialises in the integration of hardware, FPGA and software components, ensuring they function together effectively. We address compatibility, interface, and performance issues, ensuring that the subsystems are synchronized and perform as intended. Our FPGA team is tightly couple with the hardware design team to ensure that cross team requirements are validated early in the design process. The same can be said regarding software, where our software team is integrated early in the component selection process to assess risks and opportunities specific to their activity.

- Hardware Integration: Connection and configuration of the different hardware subsystems ensuring compatibility and optimizing performance.

- FPGA Integration: Configure and optimize FPGA components within the system framework.

- Software Integration: Integrate and align software applications with the target hardware, ensuring seamless interaction and functionality.

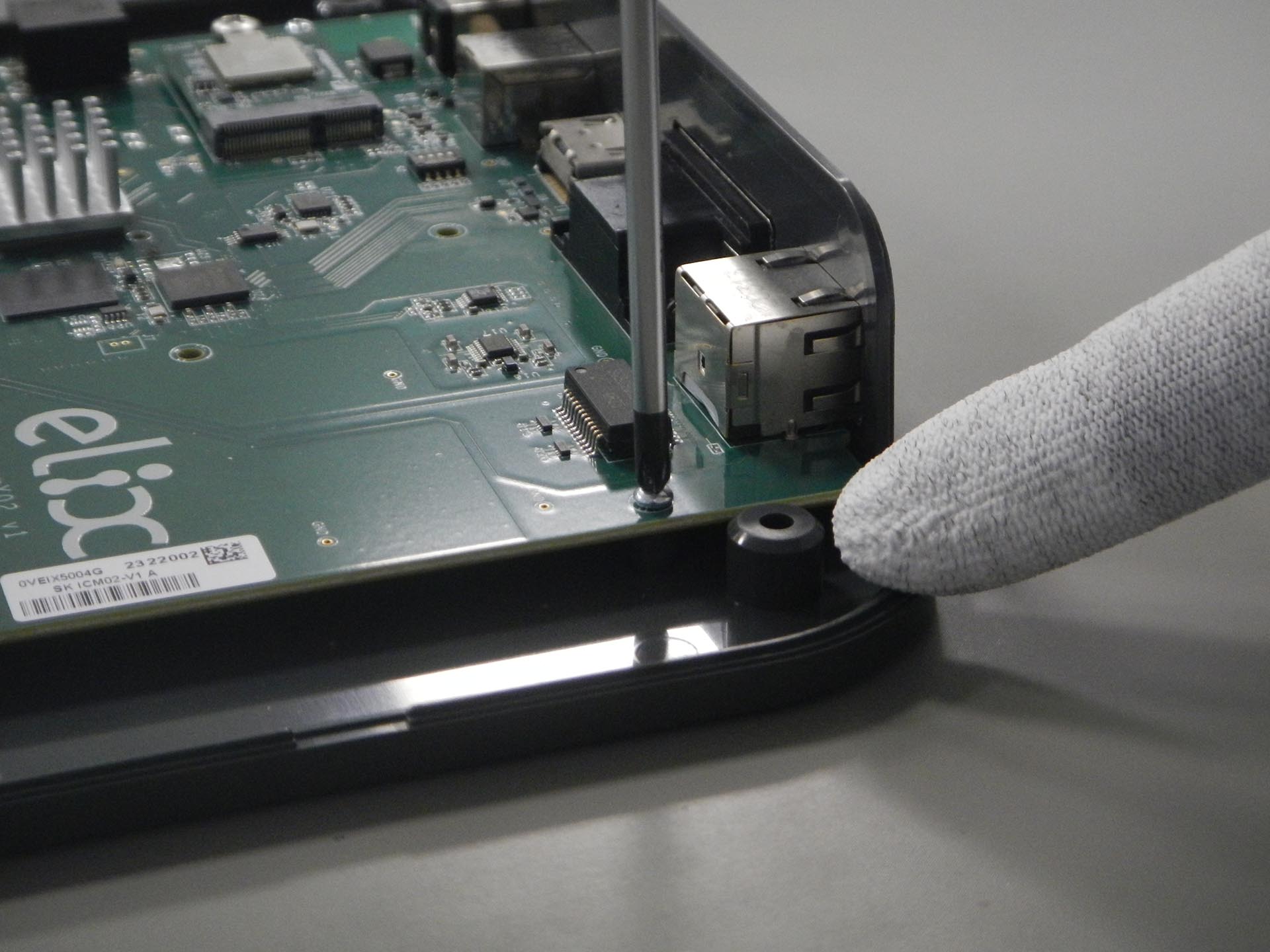

Production

First prototypes, low rate initial production, high volume

Elix’s nearshore facilities and qualified partners facilitate smooth design-to-production transitions, enabling early testing and timely adjustments to meet standards and needs.

- Elix integrates design and production processes thus reducing the time it takes to develop and launch a product.

- The ability to test designs and prototypes early in the production process helps ensure that the final product meets the desired quality standards and specifications.

- Elix’s ability to modify designs and production processes in real-time allows a fast response to changes in customer demands or market conditions.